INQUIRY

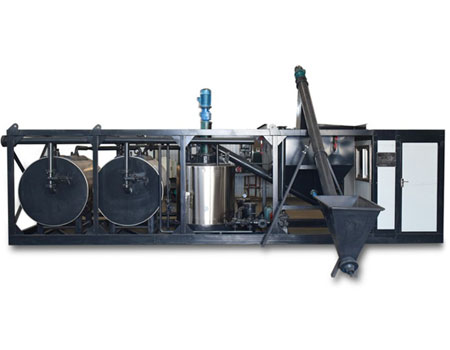

Capacity:10t/h~20t/h

Sinoroader | Main Features & Advantage:

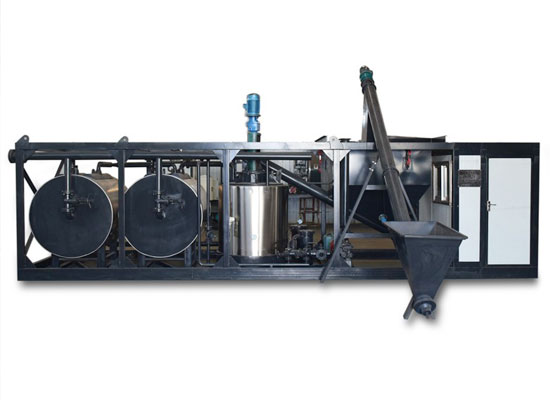

1.The bitumen pipeline has the functions of unloading oil, circulation and production.

2.The rubber asphalt pump uses a high viscosity pump.

3.Tank mixing and rubber powder lifting adopt frequency conversion start, can use places with small capacity; adjust production; protect motor and mixing equipment in all directions.

4.Two TBL26 burners, the theoretical maximum heating power of 600kw. The temperature of 20 tons of asphalt can be increased by 80Ōäā in about 2.5 hours

5.Small volume mixing tank, using knife-shaped mixing blades, breaking the block of rubber powder, can be evenly mixed with asphalt and rubber powder.

6.The tank top mixer adopts a bracket structure to isolate the heat source from the motor to ensure that the motor operates in a relatively low temperature environment.

7.The heat transfer oil circulation heating system can reduce the stirring installation position, and the relative residual at the bottom is small.

8.The heat transfer oil and asphalt are automatically controlled by temperature and are safe.

Sinoroader | Bitumen Supply System

The asphalt accurately controls the asphalt feed rate through the flow meter and the asphalt pump frequency converter.

| Model | RMB-10 | RMB-15 | RMB-20 |

| Max. Productivity (t/h) | 10 | 15 | 20 |

| Total power (kW) | 185 | 205 | 255 |

| Total weight (t) | 35 | 41 | 45 |

| Dimensions | 7350*2800*3100 | 8150*2900*3000 | 8970*3100*3000 |

Q Do customer need to have development tank already?

Q Does the stored matrix asphalt need to be heated?

Q Can equipment be loaded into containers?

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China