INQUIRY

May 26th, 2020

May 26th, 2020

The drying system is one of the main components of the asphalt mixing equipment. Its main function is to heat and dry the aggregates and heat them to the temperature required to obtain high-quality asphalt mixture. In order to eliminate the moisture in the aggregate, the drying system must provide a certain amount of heat in order to convert the moisture in the aggregate into water vapor and heat the aggregate to the required temperature. The dry-drying drum is a rotating, long cylindrical cylinder. The aggregate from the feeding belt of the cold storage unit enters the drum from the feed box, is directly contacted with the hot gas generated by the burner and is dried, and at the same time is heated to the set temperature, flows out of the aggregate outlet chute into the hot bone Material elevator.

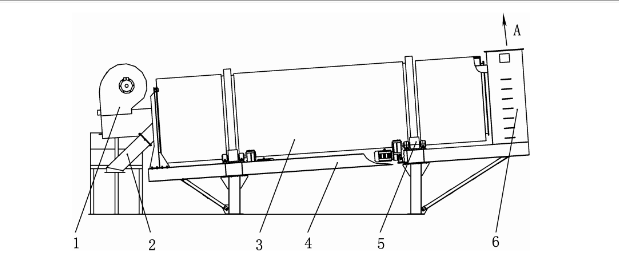

1. Burner 2. Aggregate outlet chute 3. Drying drum 4. Support 5. Drive configuration 6. Feed box A. Gas

The cylinder of the drying drum is welded by heat-resistant and wear-resistant boiler steel plate. The thermal expansion before and after heating is caused to prevent deformation caused by high temperature. There is an inclination angle between the support of the cylinder and the horizontal plane, the purpose is to make the drying cylinder in an inclined position when working, so that the aggregate continuously moves forward and flows to the discharge end during the repeated lifting process in the drum. In order to improve the heat transfer of the drying drum.

In order to change efficiency, it is necessary to limit the air entering the drying drum from the combination of the drum and the inlet and outlet boxes as much as possible. When the drum is in working state, it is not allowed to adjust the sealing devices at both ends to avoid danger.

The transmission device used to drive the dry-blaster Jian Zhite adopts Eagle wiper drive, and the four driving wheels are driving wheels. When the driving wheel is in the working state, it is not allowed to touch the driving wheel and the desired circle by hand. To avoid danger.

In order to make the aggregate move forward evenly in the drying drum and fully absorb the heat, the drum is equipped with several rows of blades bent into a certain shape.

The internal structure of the drum is divided according to function, mainly composed of the following four parts:

1. Feeding area. The blades in this part are spiral blades, whose function is to guide the aggregate into the drum and move it forward quickly.

2. Heat exchange area. In order to strengthen the heat exchange between the hot air and the aggregate, the design of the blade allows the aggregate to be lifted here many times

And freely scattered, forming a uniform material curtain, so that the hot gas can fully penetrate the material curtain and exchange heat with the aggregate.

3. Combustion zone. In order to make the fuel fully combusted, some special material-containing blades are installed in this section. It can make aggregate

In the process of moving forward, it is lifted up and clings to the inner wall of the cylinder without falling down to block the flame, and at the same time it can reach

The purpose of internal heating of aggregate. And it can also reduce the loss of incomplete combustion caused by fuel droplets being hit by aggregates.

Less loss of heat dissipation through the drum wall, reducing the damage of the heat radiation to the drum wall.

4. Discharging area. It quickly lifts the aggregate into the discharge chute of the discharge box and discharges it.

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China