INQUIRY

May 28th,2020

May 28th,2020

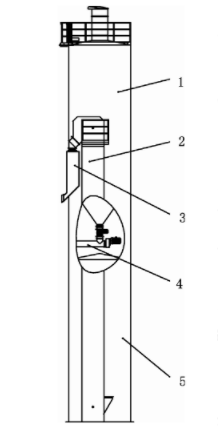

The powder system is one of the main components of the asphalt mixing equipment. Its main function is for the storage of mineral powder and the recycling of recovered powder. There are two powder tanks, one for adding mineral powder and the other one Recycle dust filter dust. The two powder tanks are composed of tank body, powder elevator, transitional powder hopper and powder adding screw conveyor. The two kinds of powder can be sent to the mixing floor by a screw conveyor according to a fixed ratio to be weighed and stirred. The functions of lifting, storing and conveying mineral powder and recovered powder can be completed separately. The main body of the powder system is a long cylindrical barrel structure (as shown). Mineral powder (using a bulk cement truck) is pneumatically transported into the upper powder tank, and then sent to the upper mixing tank by the screw conveyor for weighing and stirring; the recovered powder is sent to the bucket elevator by the screw conveyor, and then by the bucket elevator It is sent to the transitional powder hopper. There are two channels at the exit of the transitional powder hopper. If the recovered powder cannot be reused, go directly to the powder tank through the first channel; Stir upstairs to weigh and stir.

1. On the powder jar 2. Bucket elevator 3. Transitional powder hopper

4. Screw conveyor 5. Lower powder can

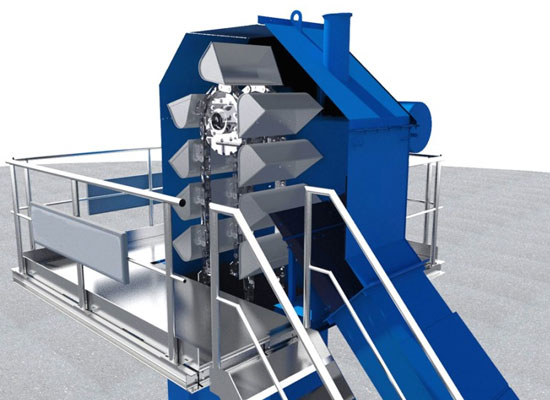

The function of the hot aggregate elevator is to lift and transport the dried hot aggregate from the drying drum to the vibrating screen located at the uppermost part of the main mixing building.The hot aggregate elevator is mainly composed of the following parts:

1. Upper section: composed of upper casing, upper cover and transmission sprocket set.

2. Lower section: It consists of the lower casing and tensioning sprocket. The lifting chain is tensioned by a screw and spring adjustment method, which can automatically adjust the rotation relaxation phenomenon caused by the wear of the chain and can buffer the additional stress caused by the sudden impact load. The sprocket is an assembled structure with a detachable rim, which has a long service life and is convenient for maintenance and replacement.

3. Middle section: It is composed of the middle casing which plays the role of support, protection and sealing. The central casing is a standard knot structure.

4. Drive: shaft-mounted helical gear reducer motor (with brake) integral drive.

5. Running part: It is composed of hopper, round return chain, chain link hook, etc. The traction parts are made of high-strength ring chains, which are made of high-quality low-carbon alloy structural steel. After heat treatment, they have high tensile strength and wear resistance, so they have reliable performance and long life. Lifting buckets are installed equidistantly on the chain.

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China