INQUIRY

Capacity:15t/h~30t/h

Main Features:

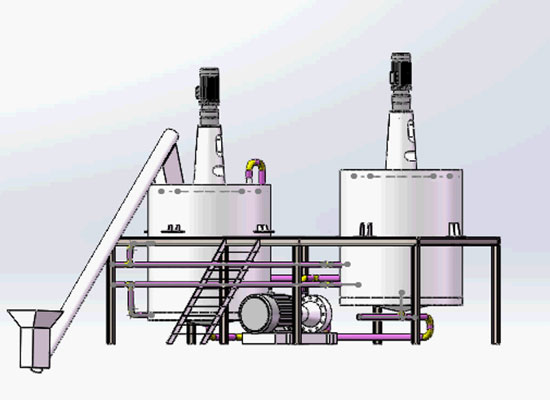

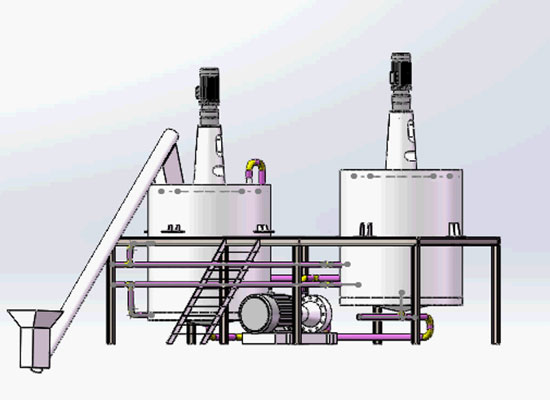

1.The whole equipment adopts container design, which has low installation cost and convenient relocation.

2.The equipment adopts rapid heating device, which can quickly heat the asphalt to the use temperature, the asphalt is evenly heated and the work efficiency is high.

3.Using high-strength motors, it can meet the production of SBS modified asphalt with polymer content up to 8%.

4.The modifier is fed into the machine using a screw conveyor that moves the material both vertically and horizontally.

5.The mixing tank is carried out by using two tanks alternately, and the ratio is accurate, so that the modifier is fully swelled, and the blending of the asphalt and the modifier is more uniform.

6.Grinding disc clearance can be adjusted by handwheel, factory clearance setting ensures asphalt is ground and homogenized under optimal conditions.The grinding disc material is made of high wear-resistant tool steel, which has strong wear resistance and long service life.The mill is heated by heat-conducting oil and has a closed-type heat preservation device.

7.The design of the moving and flat-plate flat teeth of the colloid mill is not only simple in processing, safe in use, high in running accuracy, and high in flow rate. When the polymer is subjected to extrusion shearing, the electrical energy-mechanical energy-heat energy is all completed in the same mill, which saves energy, reduces energy consumption, and achieves energy saving.

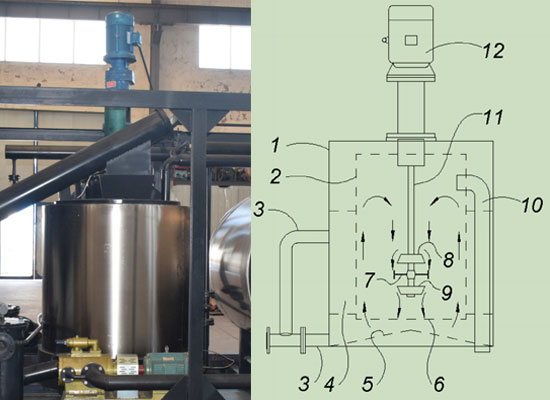

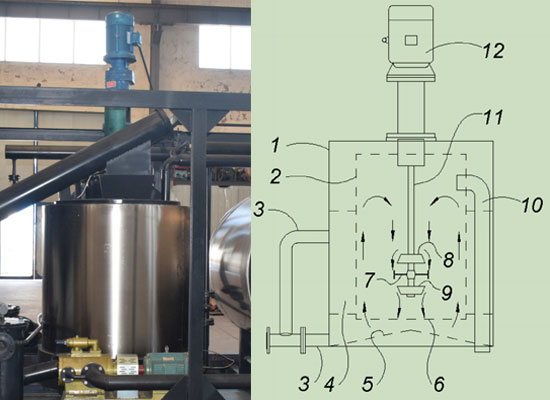

Structure and Components

Sinoroader | Grinding System

The grinding system is the most critical part of the whole equipment. The modifier and asphalt mixture are fully sheared and the modifier is evenly dispersed in the asphalt. Two high-power colloid mills are used in series or in parallel to meet any process grinding requirements. In case of failure, it can be used alone.

Sinoroader | Rapid Heating Device

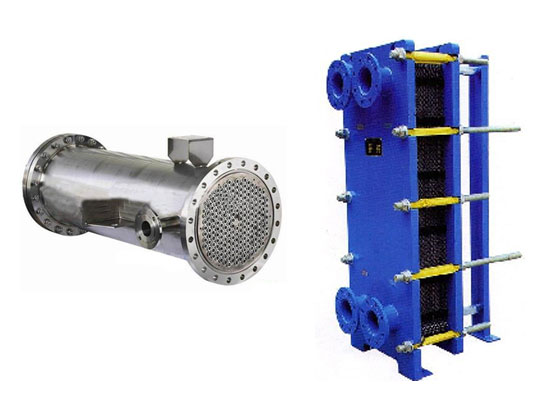

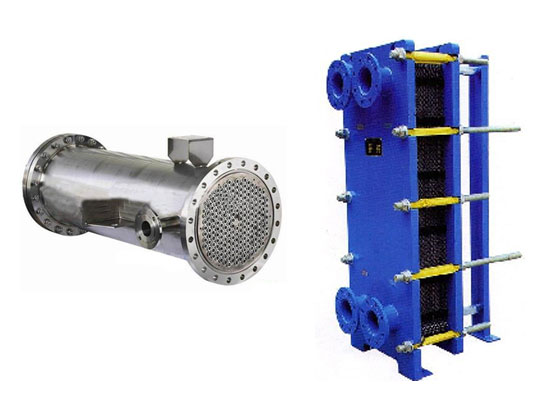

The rapid heating part uses two spiral plate heat exchangers in series to exchange heat between the asphalt and the heat transfer oil in a closed condition.It can quickly raise the asphalt by more than 50 degrees. At the same time, the pneumatic control valve and the asphalt pump speed regulation double insurance are used to adjust the asphalt heating temperature to ensure the production operation can be carried out under a very small temperature difference.

The equipment is equipped with two sets of modifier lifting devices, which transport the modifier into the swelling tank and mix with the asphalt. You can choose to operate with a hoist or a screw conveyor.

Sinoroader | Bitumen Conveying and Metering system

The high-temperature and high-viscosity volumetric metering device is adopted, and a filter is arranged in the asphalt pipeline to quantitatively transport the asphalt to the swelling tank according to the formula.

Model

PMB15

PMB20

Productivity’╝łt/h’╝ē

15

20

Heating Method

Thermal Oil

Heat exchange area of heating device’╝łŃÄĪ’╝ē

90

100

Modifier extraction capacity’╝łt/h’╝ē

4

4

Mixing tank volume’╝łm┬│’╝ē

5├Ś2

6├Ś2

Mixing power’╝łKw’╝ē

7.5├Ś2

11├Ś2

Colloid mill power’╝łKw’╝ē

65├Ś2

75├Ś2

Weight’╝łt’╝ē

15

25

Shipping packing method

40HQ├Ś1+20GP├Ś1

40HQ├Ś1+20GP├Ś1

Q What are the advantages of SBS modified asphalt?

Q What should be paid attention to when feeding modified asphalt emulsification equipment?

Q What are the advantages of modified asphalt equipment?

Q What is the modified asphalt?

Q What is a modified bitumen?

Q Which kind of modified bitumen can be produced by modified bitumen plant?

Q Does the stored matrix asphalt need to be heated?

Q How to control the ratio of modifiers?

Q How long will bitumen and modifier being mixed in the mixing tank?

Q Does the stored matrix asphalt need to be heated?

Q Which kind of modified bitumen can be produced by modified bitumen plant?

Q How to control the ratio of modifiers?

Q Is the modified asphalt equipment continuously produced?

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China